Commercial Pipe Heating – Freeze Protection and Hot Water Maintenance

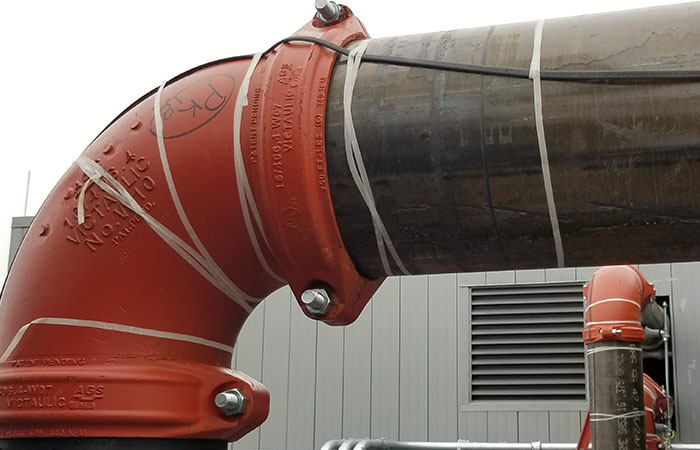

FREEZE PROTECTION – In cold locations, thermal insulation alone cannot keep pipes from freezing. A pipe freeze protection system can prevent freezing of fluids in pipes.

System Parts can include:

- CPR Heating Cable with Polyolefin Outer Jacket or Fluoropolymer Outer Jacket depending on temperature and environmental exposure

- Thermwire heating cable for light commercial or residential piping freeze protection

- CPM Heating Cable or freeze protection applications with high possible exposure temperatures, such as steam piping.

- DL Series Connection Accessories

- Ambient or Line Sensing Thermostat

- IntelliTrace electronic controls

- DL Attachment Accessories (including fiberglass tape, aluminum tape for PVC pipe, pipe straps, and caution labels)

- Insulation (provided by others)

HOT WATER MAINTENANCE – Provides commercial buildings with immediate hot water availability without expensive recirculation systems

System Parts include:

- HWM Heating Cable with Fluoropolymer Outer Jacket

- DL Series Connection Accessories

- RTBC Pipe-sensing Thermostat

- CTS Digital Thermostat and Line Sensing RTD

- DL Attachment Accessories (including fiberglass tape, aluminum tape for PVC pipe, pipe straps, and caution labels)

- Insulation (provided by others)

Use of Heat Trace in the Application:

FREEZE PROTECTION – Chromalox CPR cable is ideal for keeping metal and plastic pipes warm in commercial buildings. CPR is constructed on a self-regulating polymer core that varies its output along its entire length, saving energy and eliminating hot spots along the pipe. It can be easily cut to length, spliced, tee to more easily follow piping networks.

HOT WATER MAINTENANCE – The HWM hot water temperature maintenance system utilizes self-regulating heat trace technology. The system, consisting of the self-regulating cable, connection kits and specialized electronic controls, provides commercial buildings with immediate hot water availability without expensive recirculation systems. It provides a simple, yet energy efficient approach by providing heat at the point where heat loss occurs. Due to the parallel construction of the self-regulating cable, it can be cut to any length, spliced, tee-branched and terminated on site. With this product, energy savings may be derived from multiple sources, such as lower supply line heat loss, eliminated return line heat loss, no pump operating costs and no supply water overheating costs.

- Please note that National Electric Code requires ground fault protection (GFEP) for all heat tracing.

Important Design Notes/Best Practices:

A ground fault protection device is required by NEC to minimize the danger of fire if the heating cable is damaged or improperly installed. A minimum trip level of 30mA is recommended to minimize nuisance tripping.

Calculate heat loss based on:

- Type and thickness of Insulation

- Pipe material and diameter

- Anticipated worst case ambient temperatures

- Desired pipe maintenance temperature

Calculate number of circuits based on:

- Supply voltage

- Circuit breaker size

- Length of heat trace run